Call Us Now

07971891527( PIN:707)

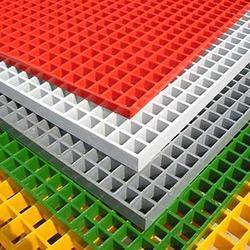

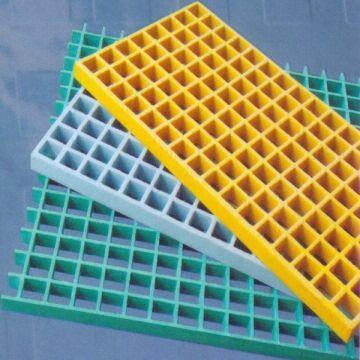

FRP Pultruded Grating

6800.00 - 49000.00 INR

Product Details:

- Shape Rectangular

- Height Usually 25 mm, 38 mm, 50 mm (other thickness on request)

- Length Standard 3 meters, Custom lengths available

- Product Type FRP Pultruded Grating

- Material Fiberglass Reinforced Plastic (FRP)

- Application Flooring, Walkways, Stair Treads, Platforms, Industrial Plants

- Surface Treatment Smooth / Anti-Skid

- Click to View more

X

FRP Pultruded Grating Price And Quantity

- 6800.00 - 49000.00 INR

- 50 , , Meter

FRP Pultruded Grating Product Specifications

- Rectangular

- Smooth / Anti-Skid

- Flooring, Walkways, Stair Treads, Platforms, Industrial Plants

- Fiberglass Reinforced Plastic (FRP)

- Available in standard and custom sizes

- Usually 25 mm, 38 mm, 50 mm (other thickness on request)

- Standard 3 meters, Custom lengths available

- FRP Pultruded Grating

FRP Pultruded Grating Trade Information

- Cash on Delivery (COD), Cash in Advance (CID), Cash Advance (CA)

- 3000 , , Meter Per Day

- 1 Week

- Yes

- Contact us for information regarding our sample policy

- In Bundle.

- Australia, Central America, Africa, Middle East, South America, Western Europe, Asia, Eastern Europe, North America

- All India

Product Description

Advantages of Pultruded Grating

-

High anti-fire

-

High anti-corrosion and anti-aging

-

High anti-slippery

-

UV Resistant

-

Light but high loaded strength

-

Long service life and maintenance free

-

Non-conduction or magnetic

-

Easy installation and rich colors

-

Various sizes and colors available upon customer request

Applications

-

Walkways and platforms

-

Cooling towers

-

CETP Plants

-

UV Resistant

-

Trench covers Stair treads Chemical Industries

-

Drainage cover

Superior Load Bearing Performance

The FRP Pultruded Grating provides exceptional load carrying capacity, making it ideal for demanding industrial applications. Its robust structure ensures reliable support in areas with heavy foot or equipment traffic, while maintaining a lightweight profile for easier handling and installation.

Resilient in Harsh Environments

Engineered for resistance against corrosive substancesincluding chemicals and acidsthis grating is perfect for environments such as industrial plants, chemical factories, and processing units. The material guarantees longevity and minimizes maintenance even in challenging conditions.

Customizable for Your Needs

Available in various colors, sizes, and thicknesses, our FRP grating can be tailored to meet specific project requirements. Whether you need different shapes, surface treatments like smooth or anti-skid, or fire retardant formulations, customization ensures performance and safety for any application.

FAQs of FRP Pultruded Grating:

Q: How does FRP Pultruded Grating contribute to user safety in industrial settings?

A: FRP Pultruded Grating is non-conductive, reducing the risk of electrical shocks, and it meets international safety standards. Its anti-skid surface options provide secure footing, and fire retardant properties can be specified for added protection.Q: What advantages does FRP grating offer over traditional metal grates?

A: Unlike metal, FRP grating is lighter, corrosion-resistant, and non-conductive, making it easier to install with reduced risk of rust or electric hazards. It also retains its structural integrity in harsh chemical and outdoor environments, ensuring long-term durability.Q: When should I consider using custom sizes or surface treatments for my grating project?

A: Custom sizes and surface treatments such as anti-skid finishes are recommended for projects with specific dimensional constraints or where enhanced slip resistance is required, such as ramps, wet areas, or unique platform layouts.Q: Where can FRP Pultruded Grating be installed for optimal performance?

A: This grating is ideal for installation in flooring, walkways, stair treads, and platforms across various industrial sites, including process plants and outdoor environments where corrosion and UV exposure are concerns.Q: What is the typical process for installing FRP grating, and is it suitable for retrofitting?

A: The grating is lightweight and easy to cut, making onsite customization and installation straightforward. It can be retrofitted over existing structures or used in new projects with minimal tools and fastener requirements.Q: How does the open area of FRP grating benefit industrial applications?

A: With an open area typically ranging from 40% to 60%, FRP grating facilitates effective drainage and ventilation, reducing water accumulation and preventing the buildup of hazardous materials on walking surfaces.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email